- Flip Chip

- WLSP

- Die Prep Services

- Final Test

- Wafer Sort

Flip Chip

TF AMD Penang is Flip Chip power house that offers various packages of Assembly and Test including FCBGA, FCPGA & FCLGA.

We are advanced technology factory with world class team, advanced infrastructure and automation capabilities.

We offer Flip Chip assembly and test services for Micro Processor, Graphic Processors, Communication & Set Top Box application. Flip Chip package types cover Single Die Package, Multi-chip Module (MCM), Coreless Substrate Package, Bare Die Package (Lidless Package), Lidded or Heat Spreader Packager and Stiffener Package.

Wafer Level Chip Scale Packaging

TF-AMD focused on developing innovative technologies by offering Wafer Level Chip Scale Packaging (WLCSP)

which provides increased functionality, improved thermal performance and finer pitch interconnection to substrate. In order to meet industry demands for turnkey WLCSP products, TF-AMD has offered the service from Wafer Probing and

Wafer Back grind as well.

In order to meet industry demands for turnkey WLCSP products, TF-AMD has offered the service from Wafer Probing and

Wafer Back grind as well. TF-AMD use fully-automated wafer back grinding equipment to achieve high level of quality for post grind wafer.

The process includes wafer backgrinding, die singulation, AOI and packing in tape & Reel. WLCSP are shipped in a Tape and Reel carrier or

waffle pack to hand various customer die sorting requirements. In order to deliver the high quality product to customer,

TF-AMD implemented 5 site inspection and Open Short Test before Tape and Reel.

Die Prep Services

TF-AMD delivers complete Die Preparation services for wafers 200mm & 300mm. Die Preparation services

are offered as part of our turnkey packaging and assembly process or as separate services based on

customer needs. With our advanced wafer processing equipment, TF-AMD offers expert backgrinding services

for wafer-level packaging.

Final Test

Final Test is a process where IC units will be tested on its reliability and electrical functionality. Final Test process done with the test cell which composed of a handler and a tester. A units will be loaded into

a Handler which connected to a Tester. The reliability and functionality of the units will be tested. The signal

data result from test site will be sent to tester to determine whether the unit is pass or fail electrically.

Good and bad unit will be segregate to the different bins. Good unit will be determine as finish goods and the bad

unit will be study and diagnose by engineer for the failure analysis. Final Test is a very important process, as it can validate and ensure only the passed and good unit been assembly

in the next process to avoid any risk of faulty in the final product.

Wafer Sort

Wafer Sort testing is performed during semiconductor device fabrication, The process of

wafer testing is to eliminate functional defects die before send for die preparation process or assembly process.

Wafer Sort testing process is performed by the test equipment called Wafer Prober

and Tester. A wafer will be loaded inside the wafer prober machine carrier and tested electrically

by using a set of microscopic contacts or probes called as probe card which connected to a Tester.

The failed die will be mark with a small dot of ink.

The result of the testing will be populated in the Wafer Map and it will be used for assembly process for picking the good dies.

Wafer Sort test is very important as it can detect and remove the detective dies in the earlier stage and saves the considerable cost of

assembly or test the faulty devices in the next process stage.

TF-AMD has an internal reliability laboratory managed by experienced and skilled engineers.

Products are subjected to stringent reliability qualification requirements during new product introduction,

new material qualification and periodic reliability monitoring program.

These reliability tests carried out are based on international standards such as JESD, AEC-Q100 and customer special

requirements to ensure that products exhibits a high degree of reliability robustness for customer satisfaction.

Our aim is to deliver superior quality, reliability, and services to our customers.

Baking Oven

⋆ Pre-conditioning

⋆ Moisture Release

⋆ Max Temperature: 300°C

⋆ Standard Ref: JESD22A103

Moisture Soak Chamber

⋆ Temperature Range: -40°C to 180°C

⋆ Humidity Range(%RH):20 to 90

⋆ Standard Ref: J-STD-020

Reflow Furnace

⋆ 8 Heating Zone & 2 Cooling Zone

⋆ Around 10 minutes per cycle

⋆ Standard Ref: J-STD-020

Temperature Cycle Chamber

⋆ 2 Cycle per Hour

⋆ Temperature Range (°C): -70°C to 180°C

⋆ Standard ref: JEDEC22a104

High Accelerated Temperature/Humidity Stress Test

⋆ Temperature Range (°C): 105°C to 150°C

⋆ Humidity Range (%RH): 65 to 100

⋆ Standard Ref: JESD22-A118

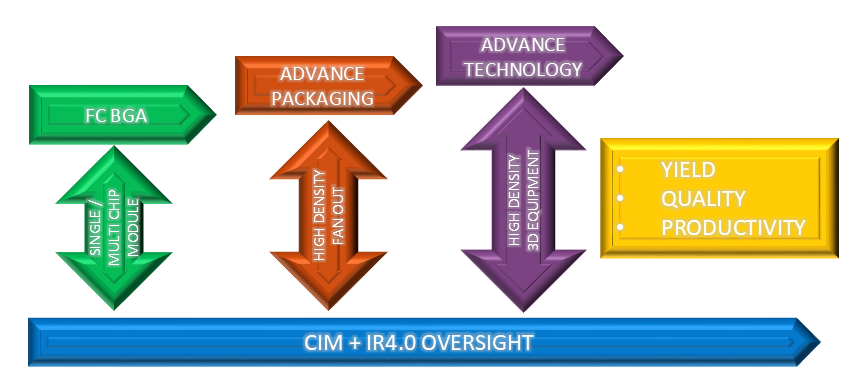

Automation

Comprehensive suite of solutions in Computer Integrated Manufacturing (CIM) and

Hardware System Intergration that moving towards a high level of Automation to

oversight on Product Quality, Yield and Productivity.

×

![]()

TF-AMD Smart Factory

Manufacturing Execution System

Collection of process and related information for:

◉ Flexible Route management for different product and process flows.

◉ Management of the working order and material WIP Planning, Scheduling and Dispatching.

◉ Maintaining product high traceability in unit level for engineering data collection.

◉ Tracking of WIP quantity of good & reject for the complete process yield data collections.

TF-AMD Industrial Revolution 4.0

Adoption of Industrial Revolution 4.0 in Automation Road Map towards Smart Manufacturing and that includes a few major automation technology which is:

◉ Internet of Things (IoT)

◉ System Integration

◉ Big Data Analytics

◉ Autonomous Robotic

◉ Artificial Intelligence

Cell Controller

Cell Controller provide interface between equipment/sensors and CIM systems.

◉ Intergration to Real-Time for factory data and closed loop with Quality Error Prevention System.

◉ One Touch Automation for Flow standardization and simplification.

Quality Control

By using SPC/PCS, Recipe Management System and Fault Detection classification in real time for:

◉ Production verification and auto control.

◉ Data collection and process performance monitoring.

◉ System Auto Alert and react base on OCAP.

TF-AMD Smart Factory